Steel

Products on a wide range of steelmaking equipment.

We develop, design, and manufacture a wide range of related equipment for steelmaking and shipping in the ironmaking process. We can meet diverse specifications to meet your needs.

LINE UP

-

01.

Electric Binding Apparatus

Binding Apparatus

Developed the first electric type in Japan.

Limit power consuming to operation only can save energy. It also can reduce noise and contribute to environmental measures. Maintenance and adjustment work of hydraulic equipment that requires a high skill become easy because of the numerical control by electrification. You will be freed from troublesome oil management. -

02.

Binding Apparatus

More than 700 units have been delivered.

Reinforced steel bars, round steel bars, and shaped steel are bound with annealing wires (SWRM). It is possible to select from a diverse lineup according to the product shape and size.

Annealing wires can be replaced quickly.

Major consumable parts are stocked, so it is possible to promptly supply them.

We provide support for your overhaul and maintenance. -

03.

Number Counting Device and

Separation EquipmentCapacity Steel bars can be counted and

separated at the speed of 12 bars per second

with high accuracy.This equipment can be installed in the finishing machine of the rolling mill that can count reinforced bars and round steel bars and separate them by the specified number of bars at high speed. Highly accurate counting can be conducted by the false positive function and separation can be accurately carried out by the separation machine through the link arm motion. Product size can be set easily by replacing the guide and wheel.

※ We also have the experience which bar steel end face counting by image recognition technology. -

04.

Automatic Tagging Machine

Automatic Tagging can realize

labor-saving and enhance

traceability.This machine will attach tag with product information printed issued by the tag issuing machine to the end section of the products bound using the φ 2.0 mm annealing wire in the slinging part in the finishing machine.

Traceability will also improved by automatically attaching data-managed labels in cooperation with the production management data system of the entire factory. Combine with binding machine, tag attaching also be possible on binding line. -

05.

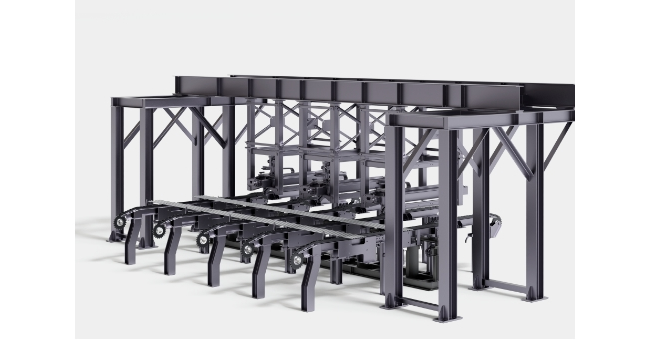

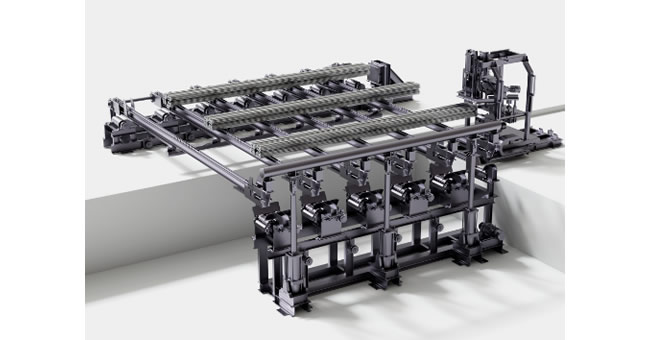

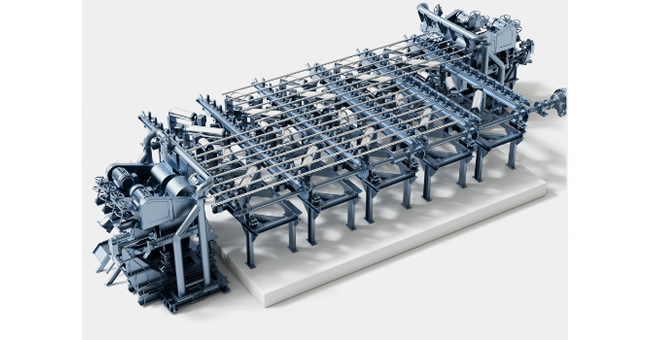

Steel Bar Finishing Equipment

After a set number of rebar bars and round steel bars are counted

After a set number of rebar bars and round steel are counted, they are automatically bundled and prepared for shipment.We offer the optimum equipment configuration for each customer’s plant for collecting and sorting steel bars and round steel.

We can reduce the occurrence of spoilage during the process, and our proprietary counting and separation equipment and automatic bundling machines enable high-speed, high-precision sorting and tagging.

In addition, the traceability of product information can be ensured by using a tagging machine. -

06.

Shaped steel Stacking Equipment

Shaped steel such as angle steel, flat steel,

I-steel, H-steel, channel steel, etc., can be

automatically stacked in the preset

style of packing.For angle steel, tapered steel, and channel steel, a stable stacking can be done by combining the forward and reverse rotation.

We have delivered many stacking equipment of various types and capacities to more than 30 rolling plants at home and abroad, and we will engineer stacking equipment tailored to customer requests.

We also have results in hexagonal pipe stacking. -

07.

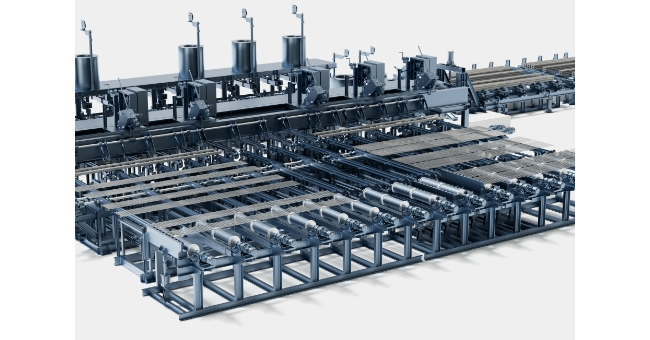

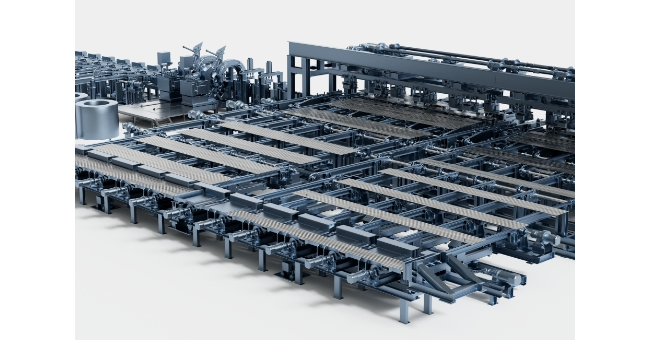

Billet-Conveying Equipment

Direct transportation from the continuous

casting machine to the rolling mill.This equipment directly transports billets cut for each strand to a heating furnace or rolling equipment.

In the case of conveyance to the heating furnace, by enabling the conveyance of the billets at high temperatures, a reduction in the heating time and furnace fuel can be achieved.

In the case of transportation to a heating furnace, it is possible to reduce the reheating time and fuel in the furnace by transporting it in a high temperature state.

In the case of transportation to a rolling mill, it is possible to significantly reduce the basic unit by reducing the number of processes.

“Cool individually one by one”

Bending can be reduced with equipment that evenly cools products transported by pushers, etc. one by one with fixed and movable rechens. We plan efficient equipment that matches the layout of the existing factory. -

08.

Billet-Marking Device

“Lettering on the end face of billets at

high temperatures.”The production history with respect to each steel bar can be accurately grasped. This can be applied to inventory control systems by combination with a recognition device. Therefore, it is ideal for quality assurance and the traceability of steel materials.

-

09.

Chamfering Equipment

“This equipment chamfers the end face

of the product on the special steel bar

inspection equipment.”Continuously chamfer the edge of end-face 1 by 1 by pushing the rotating steel bar against a grinder while being transversely fed. Grinding of the cut surface on the edge can be carried out at the same time.

Installed a dust collector on the grinder can prevent dust discharge to contributes to environmental measures.

We have a number of results with special steel makers and will make a plan meeting the processing capacity and product size and length. -

10.

Auxiliary equipment for Flaw Detecting Machine

“This is an auxiliary equipment for flaw

detection for special round bar steel and pipe.”“This is an auxiliary equipment for flaw detection for special round bar steel and pipe.”

We design and construct lifting & traveling device for flaw detector, pinch roller, back /forth transport table, water circulation device etc. with specifications that match the different flaw detectors from each manufacturer. In the case of water immersion detection of pipes, END TO END roller transportation is also possible. -

11.

Special binding machine

Customize binding specifications.

We manufacture a binding machine that matches the product size and existing equipment using standard model units.

・Pulp binding machine

・Coil binding machine

・Parallel knot type wire binding machine