Takigawa Group’s

Commitment to SDG’s

(Sustainable Development Goals)

In addition to our basic lifestyles of daily clothing, food, and shelter, our lives are made up of a variety of cultural and economic activities. Needless to say, the products produced by industrial machinery are indispensable to these cultural and economic activities.

As a manufacturer of industrial machinery, Takikawa Kogyo aims to maximize customer satisfaction by manufacturing such products, while contributing to the achievement of the SDGs through business activities based on sustainable approaches, including the active use of renewable energy.

We believe that the continuation of these efforts is one of the community and social contribution activities we should fulfill as a responsible corporate citizen.

Social Contribution through

Enhanced Employee Education

We are committed to employee education. In addition to training and education intended to improve professional skills, we provide opportunities for “learning,” including self-development, and opportunities to grow as well-rounded members of society.

In addition, the “Takigawa Group’s Rules of Conduct” deny all forms of discrimination and emphasize the importance of equality and fairness, and we will contribute to the development of a healthy society free of discrimination by incorporating these principles into our employee education.

We believe that promoting employee job satisfaction through the development of this kind of internal education will also be beneficial to their health.

Contribution to Society through

Environmental Initiatives

plant, which is already in operation, we are preparing to add a new solar power generation system on an adjoining site. In addition, all lighting fixtures in the head office have been converted to LEDs to conserve power.

In addition to the above, we are promoting the use of environmentally friendly vehicles for company use, and are working to reduce the ratio of gasoline-powered vehicles in new purchases.

We are actively engaged in technological innovation in the development

We are actively engaged in technological innovation in the development of our core products.

One example is the electrification of our mainstay bundling machines. While hydraulic drive had been the norm in the industry, we have developed a new electric strapping machine that reduces the burden on the environment, and this has been highly praised by many of our business partners.

Takigawa Group’s

Carbon Neutral Initiatives

In order to leave a beautiful planet for our descendants, we aim to protect the local and global environment by reducing energy and resource consumption, recycling, reducing waste, preventing environmental pollution, and improving product quality. With this philosophy, we will continue our efforts to become carbon neutral.

Responding to Climate Change

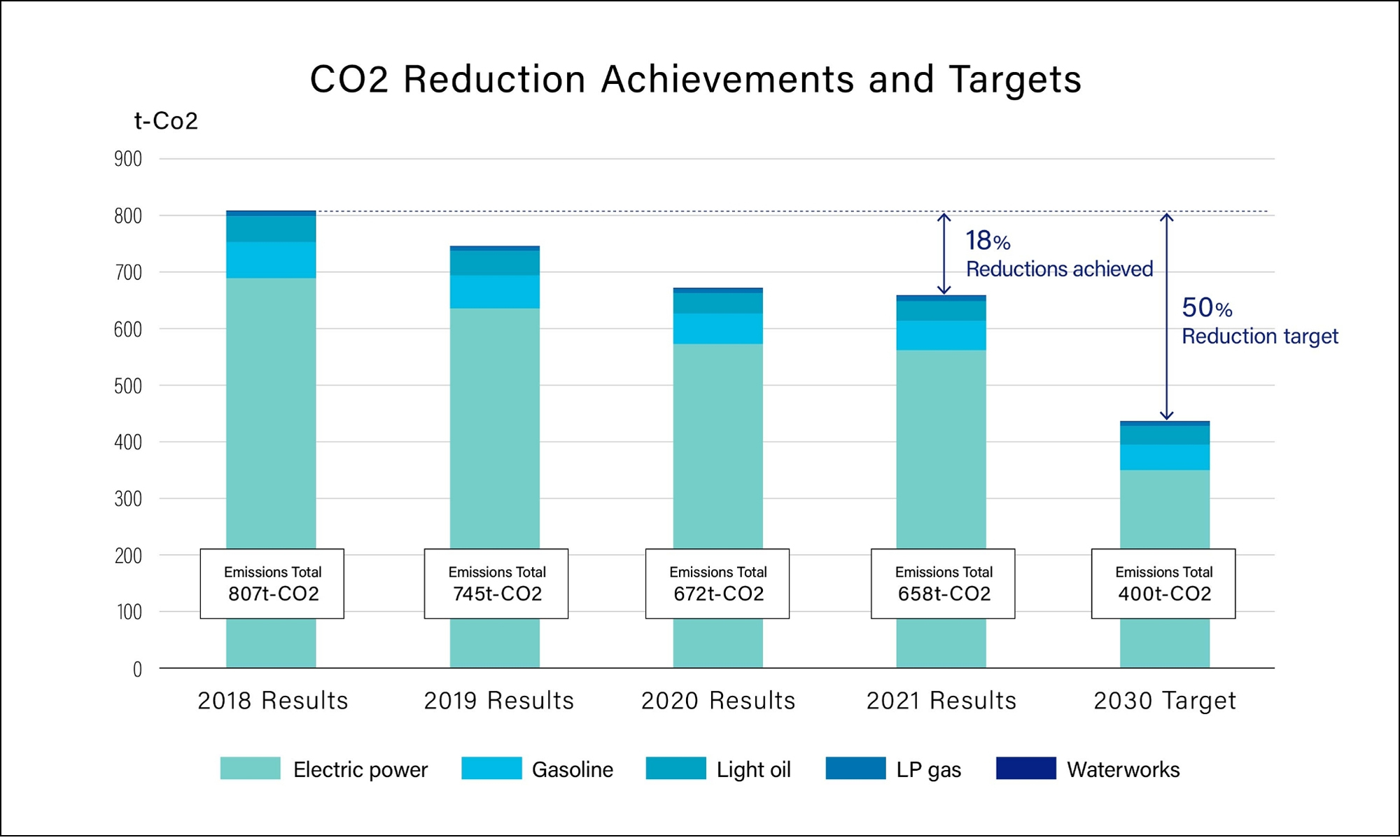

Reduction of CO2 emissions in production activities

We have set a goal of reducing CO2 emissions generated by our production activities by 50% in FY2030 compared to FY18. The photovoltaic power generation equipment we have installed as a key measure to achieve this goal has enabled us to cover approximately 40% of the electricity at our headquarters plant with renewable energy. In addition, all lighting equipment throughout the Group has been converted to LED. In the future, we will actively introduce electric vehicles to further promote energy-saving activities.

| 2018 Results | 2023 Results | 2030 Target | |

| Reduction of CO2 emissions in production activities |

785t-CO2 | 631t-CO2 | 392t-CO2 |

| Reduction of CO2 emissions in production activities |

|

| 2018 Results | 785t-CO2 |

| 2023 Results | 631t-CO2 |

| 2030 Target | 392t-CO2 |

*Effects of the introduction of solar power generation equipment

Solar power generation facilities were installed on the rooftop of the Head Office’s Plant No. 4 (approx. 1,400 m2) and on a nearby landfill site (approx. 2,300 m2). As a result, CO2 emissions were reduced by approximately 239 tons per year.

181.5kw power plant on the rooftop of the No. 4 plant

of the Head Office

244.8kw power plant on land developed on the north side of the Head Office

*Effects of LED Lighting

Replaced 204 mercury lamps in all group plants with LED lighting. In addition, 100% of the lighting in the welfare building was also converted to LED. This has resulted in a reduction of approximately 47 tons of CO2 emissions per year.

*Installation of energy-saving machine tools

In 2022, an energy-saving machine tool (INTEGREXe670H) manufactured by Mazak was installed in the main factory. This will reduce CO2 emissions by approximately 282 kg per year.

Headquarters plant INTEGREXe670H made by Mazak